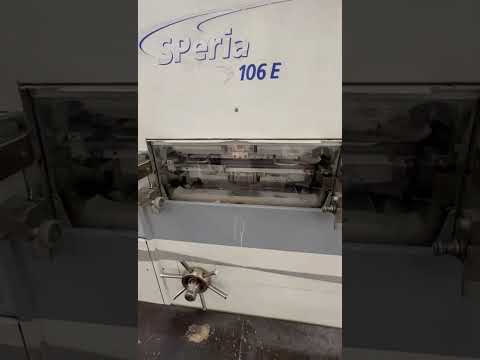

Punching machineBobst

Autoplatine Speria 106 E

Punching machine

Bobst

Autoplatine Speria 106 E

سال ساخت

۲۰۰۶

وضعیت

کارکرده

موقعیت

Hlavní město Praha

تصاویر نشان میدهند

نمایش نقشه

اطلاعات دستگاه

قیمت و مکان

- موقعیت:

- Jezkova 1054/10, 13000 Praha 3, Česká republika

تماس بگیرید

جزئیات پیشنهاد

- شناسه آگهی:

- A20248585

- بهروزرسانی:

- آخرین بهروزرسانی در ۱۷.۰۹.۱۴۰۴

توضیحات

Bobst Autoplatine Speria 106 E

STANDARD EQUIPMENT

MACHINE

- Centerline system for quick job changeover.

- Electronic sheet travel monitoring system.

- Adjustable centering at the stripping station.

- Control cabinet air conditioning unit.

- Bobst electronic control system C.U.B.E. (Control Unit Bobst Electronic).

This microprocessor-based Bobst system allows the operator to easily manage, visualize, and monitor the machine’s various functions and components.

- Main motor with frequency inverter control.

FEEDER

- Pile tray with handle for easy manual lateral alignment during production.

- Synchronization device ensuring proper sheet arrival to the front lays when the machine is stopped.

- Automatic pile lifting controlled by pressing foot.

- Rear pile guides (operator side and opposite operator side).

- Adjustable side blowers with Centerline markings.

- Suction unit.

FEED TABLE

- Feed table with anti-static stainless steel covering.

- Feed table entrance equipped with lateral ramps.

- Four front lays, pairwise adjustable, with front register control.

- "Pull" guide (operator side), adjustable with Centerline markings and side register control.

- Double sheet detector.

- Support plates at platen station entry.

- Sheet hold-down mechanism (guides sheets to front lays).

- Upper frame with manual lifting device.

- Upper transport system for paper, paperboard, and corrugated board.

- Transport belts with lateral guides and automatic tensioning system.

PLATEN

- Gripper reopening device.

- Centering and locking for equipment.

- Locking the chase to the upper beam.

- Cutting force measurement with strain gauge.

1 synthetic supporting plate.

1 upper chase: fixed bottom plate.

1 cutting plate.

WASTE STRIPPING STATION

- Air-cylinder-driven upper frame lifting.

1 upper pull-out frame (with crossbars and clamps).

1 lower pull-out frame.

DELIVERY

- Pile tray.

- Front jogger.

- Adjustable rear and side joggers with Centerline markings.

Bwedpfjxl Talox Af Dsi

- Braking brush.

- Manual non-stop rack.

AVAILABLE EXTRAS

B MACHINE

1 B-1 Raised machine base

C FEEDER

1 C-4 Manual non-stop device

E PLATEN

1 E-5 Compensating plate

1 E-55 Micro-adjustable supporting plate centering

F WASTE STRIPPING STATION

1 F-31 Quick-lock device for the upper pull-out frame

آگهی به صورت خودکار ترجمه شده است. احتمال بروز اشتباه در ترجمه وجود دارد.

STANDARD EQUIPMENT

MACHINE

- Centerline system for quick job changeover.

- Electronic sheet travel monitoring system.

- Adjustable centering at the stripping station.

- Control cabinet air conditioning unit.

- Bobst electronic control system C.U.B.E. (Control Unit Bobst Electronic).

This microprocessor-based Bobst system allows the operator to easily manage, visualize, and monitor the machine’s various functions and components.

- Main motor with frequency inverter control.

FEEDER

- Pile tray with handle for easy manual lateral alignment during production.

- Synchronization device ensuring proper sheet arrival to the front lays when the machine is stopped.

- Automatic pile lifting controlled by pressing foot.

- Rear pile guides (operator side and opposite operator side).

- Adjustable side blowers with Centerline markings.

- Suction unit.

FEED TABLE

- Feed table with anti-static stainless steel covering.

- Feed table entrance equipped with lateral ramps.

- Four front lays, pairwise adjustable, with front register control.

- "Pull" guide (operator side), adjustable with Centerline markings and side register control.

- Double sheet detector.

- Support plates at platen station entry.

- Sheet hold-down mechanism (guides sheets to front lays).

- Upper frame with manual lifting device.

- Upper transport system for paper, paperboard, and corrugated board.

- Transport belts with lateral guides and automatic tensioning system.

PLATEN

- Gripper reopening device.

- Centering and locking for equipment.

- Locking the chase to the upper beam.

- Cutting force measurement with strain gauge.

1 synthetic supporting plate.

1 upper chase: fixed bottom plate.

1 cutting plate.

WASTE STRIPPING STATION

- Air-cylinder-driven upper frame lifting.

1 upper pull-out frame (with crossbars and clamps).

1 lower pull-out frame.

DELIVERY

- Pile tray.

- Front jogger.

- Adjustable rear and side joggers with Centerline markings.

Bwedpfjxl Talox Af Dsi

- Braking brush.

- Manual non-stop rack.

AVAILABLE EXTRAS

B MACHINE

1 B-1 Raised machine base

C FEEDER

1 C-4 Manual non-stop device

E PLATEN

1 E-5 Compensating plate

1 E-55 Micro-adjustable supporting plate centering

F WASTE STRIPPING STATION

1 F-31 Quick-lock device for the upper pull-out frame

آگهی به صورت خودکار ترجمه شده است. احتمال بروز اشتباه در ترجمه وجود دارد.

تأمینکننده

توجه: به صورت رایگان ثبتنام کنید یا وارد شوید, تا به تمام اطلاعات دسترسی داشته باشید.

ارسال درخواست

تلفن & فکس

+420 229 ... آگهیها

این آگهیها ممکن است برای شما نیز جالب باشند.

آگهی کوچک

Leinfelden-Echterdingen

Leinfelden-Echterdingen

۴٬۱۰۴ km

Konica Minolta6120

آگهی کوچک

اسلوونی

اسلوونی

۳٬۶۵۳ km

Glunz & JensenTiger 125 Premium

آگهی کوچک

Alkmaar

Alkmaar

۴٬۴۸۳ km

KAMAProcut 58

آگهی کوچک

آلمان

آلمان

۴٬۰۶۹ km

Honsel & Co.722

آگهی کوچک

Valea Mare-Podgoria

Valea Mare-Podgoria

۲٬۸۳۹ km

MAN Roland704

آگهی کوچک

Henstedt-Ulzburg

Henstedt-Ulzburg

۴٬۱۷۶ km

PolarN 115 PLUS

آگهی کوچک

Alsfeld

Alsfeld

۴٬۱۴۰ km

BobstSP142ER

آگهی کوچک

Radom

Radom

۳٬۳۷۸ km

Wohlenberg 132 TSPaper Cutting Machine

آگهی کوچک

Wuppertal

Wuppertal

۴٬۲۹۶ km

Jakob Müller Frick AGNF42 4/42mm

آگهی کوچک

Zaandam

Zaandam

۴٬۴۷۹ km

MBOK 66 KL/6

آگهی شما با موفقیت حذف شد

یک خطا رخ داده است