Classifier millHosokawa Alpine

ZPS 315

Classifier mill

Hosokawa Alpine

ZPS 315

سال ساخت

۱۹۹۶

وضعیت

کارکرده

موقعیت

Augsburg

تصاویر نشان میدهند

نمایش نقشه

اطلاعات دستگاه

- نام دستگاه:

- Classifier mill

- تولید کننده:

- Hosokawa Alpine

- مدل:

- ZPS 315

- سال ساخت:

- ۱۹۹۶

- وضعیت:

- کاملاً بازسازیشده (کارکرده)

قیمت و مکان

- موقعیت:

- Peter-Dörfler-Straße 13-25, 86199 Augsburg, DE

تماس بگیرید

فروش ماشینآلات

آیا قبلاً دستگاه دست دوم خود را آگهی کردهاید؟

از طریق Machineseeker بدون کمیسیون بفروشید.

اطلاعات بیشتر درباره فروش ماشینآلات

اطلاعات بیشتر درباره فروش ماشینآلات

جزئیات پیشنهاد

- شناسه آگهی:

- A8823965

- بهروزرسانی:

- آخرین بهروزرسانی در ۲۲.۱۱.۱۴۰۳

توضیحات

Used Hosokawa Alpine Zirkoplex ZPS 315 classifier mill

A HOSOKAWA ALPINE Originals machine

Refurbished by the original manufacturer

Csdpfx Afskqlf Sjnerh

Use of original components only

Original manufacturer warranty

Guaranteed manufacturer spare parts supply

Short lead time

Before delivery, the machine is overhauled, all wear parts are revised and exchanged if needed and customized to your specific needs

Possibility to provide all additionally required peripherals or adapt to existing production plant

We are also interested in buying back disused HOSOKAWA ALPINE machinery

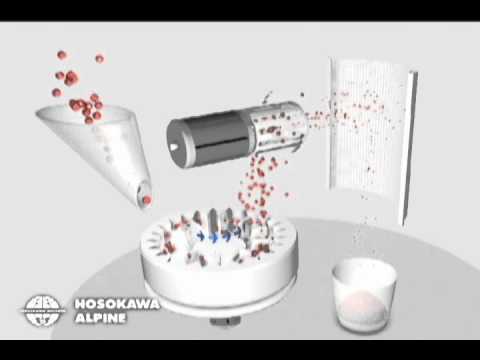

The Hosokawa Alpine Zirkoplex ZPS impact classifier mill is perfect for the fine grinding of different dry materials with a precise control over the particle´s top cut thanks to its integrated classifier wheel design, using the Alpine classifier ATP. It can be used to pulverize different products and within different industries where micronization might be needed, such as minerals, chemicals, food, pharma, etc. The comminution takes place in the bottom part of the grinding chamber where the rotor plate fitted with grinding tools (hammers or pins) impacts and projects the particles against the liner in order to break them. Within the same chamber, the air circulation brings the fines to the rotating classifier wheel where oversize grains are rejected to then return to the griding zone for reprocessing, whereas the fine particles make it through the classification step to the next stage, normally the filter. Thanks to the required process air volume, reduced temperature increase during grinding is to be expected compared to other granulation technologies. Adjusting the final particle size distribution can be easily done by changing different parameters, such as the speed of the grinding rotor or disc and the classifier wheel, air volume, feeding rate, etc.

Material of construction: stainless steel for product contacted parts

Without wear protection

Non Pressure Shock Resistant (NPSR), non-ATEX

Scope of supply:

Hosokawa Alpine ZPS 315 mill with motors, a set of grinding tools of choice and installation table

A HOSOKAWA ALPINE Originals machine

Refurbished by the original manufacturer

Csdpfx Afskqlf Sjnerh

Use of original components only

Original manufacturer warranty

Guaranteed manufacturer spare parts supply

Short lead time

Before delivery, the machine is overhauled, all wear parts are revised and exchanged if needed and customized to your specific needs

Possibility to provide all additionally required peripherals or adapt to existing production plant

We are also interested in buying back disused HOSOKAWA ALPINE machinery

The Hosokawa Alpine Zirkoplex ZPS impact classifier mill is perfect for the fine grinding of different dry materials with a precise control over the particle´s top cut thanks to its integrated classifier wheel design, using the Alpine classifier ATP. It can be used to pulverize different products and within different industries where micronization might be needed, such as minerals, chemicals, food, pharma, etc. The comminution takes place in the bottom part of the grinding chamber where the rotor plate fitted with grinding tools (hammers or pins) impacts and projects the particles against the liner in order to break them. Within the same chamber, the air circulation brings the fines to the rotating classifier wheel where oversize grains are rejected to then return to the griding zone for reprocessing, whereas the fine particles make it through the classification step to the next stage, normally the filter. Thanks to the required process air volume, reduced temperature increase during grinding is to be expected compared to other granulation technologies. Adjusting the final particle size distribution can be easily done by changing different parameters, such as the speed of the grinding rotor or disc and the classifier wheel, air volume, feeding rate, etc.

Material of construction: stainless steel for product contacted parts

Without wear protection

Non Pressure Shock Resistant (NPSR), non-ATEX

Scope of supply:

Hosokawa Alpine ZPS 315 mill with motors, a set of grinding tools of choice and installation table

تأمینکننده

توجه: به صورت رایگان ثبتنام کنید یا وارد شوید, تا به تمام اطلاعات دسترسی داشته باشید.

ثبت شده از: 2019

ارسال درخواست

تلفن & فکس

+49 821 2... آگهیها

این آگهیها ممکن است برای شما نیز جالب باشند.

آگهی کوچک

Augsburg

Augsburg

۳٬۹۷۳ km

Hosokawa AlpineZPS 315

آگهی کوچک

Arnsberg

Arnsberg

۴٬۲۴۴ km

Hosokawa AlpineZPS 315

آگهی شما با موفقیت حذف شد

یک خطا رخ داده است